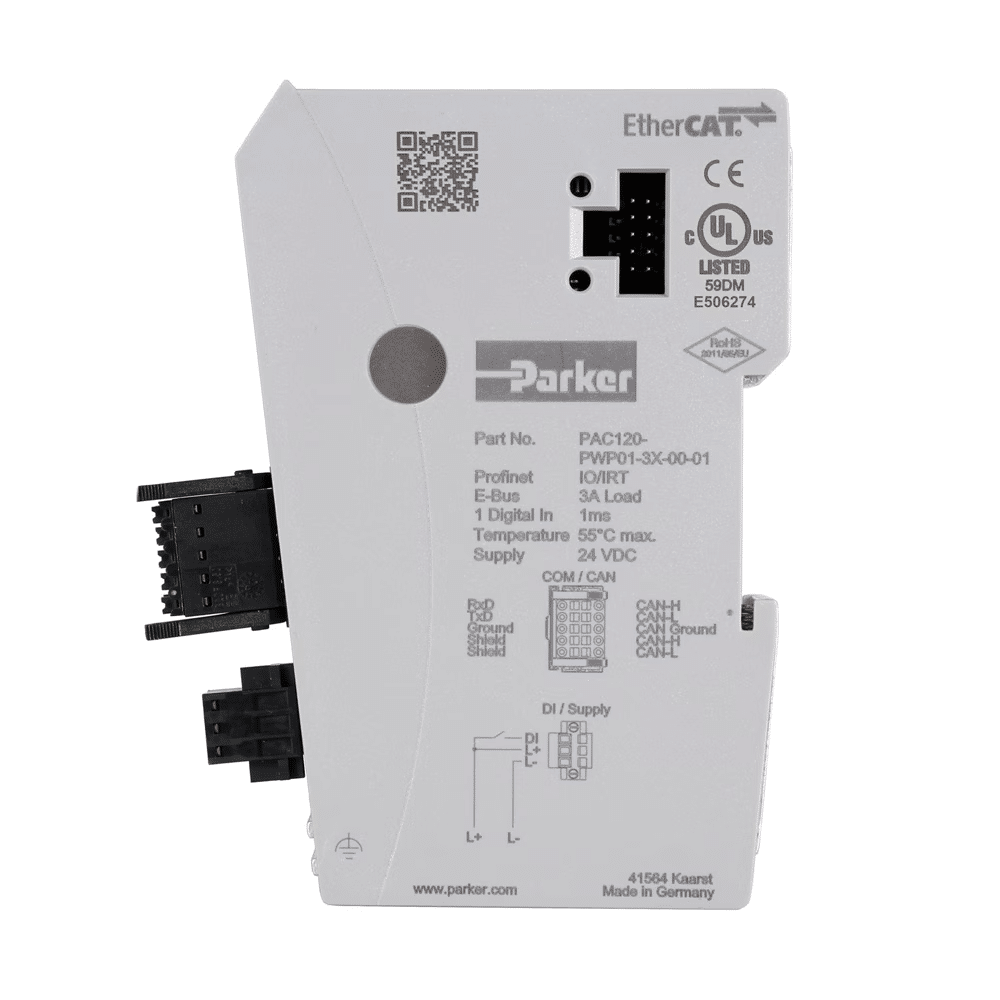

Product type : Programmable Automation Controller

Mounting type: 35 mm DIN rail

Language: IEC 61131-3

Software: Application: CODESYS V3 Soft SPS

Inputs/Outputs : 1xDI 1 ms

Operating system: Linux RT

Minimum operating temperature: 0°c

Specifications complied with: CE, EMC, UL, ROHS

Technology : Hydraulics

Electrical connection: 36-pol spring-type connector with mech.ejector

Housing material: Aluminium strap, plastic, IP20

Mounting position: Vertical, stackable

Number of axes : Up to 40 (with PACHC)

Visualization: Web visualization

CPU: i.MX6 SoloX Freescale 1 GHz

Supply voltage: 24VDC

Maximum operating temperature: 55°C

Weight: 0.2 kg

Product style : Mini-IPC

Watertightness level : IP20

Powerful, integrated, and designed for the global machine market, the EtherCAT based Parker motion controller helps OEMs produce efficient, high-performance control systems based on the IEC 61131-3 and PLCopen Motion standards. The PAC combines machine logic, signal handling and high-speed motion control into a standard based, performance driven, fan-less and easily mountable din rail solution. Equipped with a native, real-time EtherCAT bus, a modular interface slot, standard Ethernet and USB ports plus a built-in SD-card slot and the supported fieldbus options Profinet Slave, EtherCAT or EtherNet/IP the controller can be easily integrated and is suitable for a wide range of applications. Programmed with CODESYS, efficient and powerful control systems can be designed based on IEC61131-3 and PLCopen motion standards. Offering the OPC UA server the controller is the perfect device for industry 4.0 communication Markets:

◦ Factory Automation

◦ Vehicle Assembly Facilities

◦ Food & Beverage

◦ Textile, Paper

◦ General Automation

Features/Benefits:

– Seamless integration into existing plant networks maximizes machine productivity

The Parker motion controller comes standard with a variety of onboard communication protocols, including OPC UA Server, EtherCAT and additional options for Ethernet/IP, Profinet.

– Quick and Easy commissioning time

Advanced Debugging Tools and Simulation Runtime as well as standardized and object oriented programming, allowing faster code generation and modular code reuse. full suite of IEC61131-3 programming languages and PLCopen motion control function blocks).

– High modularity support modular machines

Connectivity to a variety of popular 3rd party devices with Modular 1/0 and communication interfaces.

– Peace of mind with robust, industrial grade device

Thanks to removable storage media and fan-less operation. No moving parts.

Applications:

◦ Packaging Machines

◦ Material forming machines

◦ Handling machines

◦ Converting and plastic machines

◦ Printing & Marking Equipment